N - Nuclear Stainless Steel

- Remote handling stainless steel

- Chemical & radiation resistant

- Compliant with nuclear Quality standards

- Push-Pull latching system with alignment guide

- For extreme environments

| Description | Description Flawless performances in highly regulated environments such as nuclear hot cells | Description High water pressure screw locking connectors designed for demanding marine and underwater applications | Description Single contact high voltage connectors in high grade materials |

| Locking | Locking Push-Pull telemanipulator | Locking Screw locking | Locking Push-Pull |

| Size | Size 4 sizes from ø 22.0 to ø 45.0 mm (plugs) | Size 6 sizes from Ø 17.2 to 50.0 mm (plugs) | Size 3 sizes from Ø 13.0 to 47.0 mm (plugs) |

| Keying | Keying 2 keyway | Keying 4 keyway | Keying No keyway (unipole) |

| Shell Types | Shell Types Special shell design | Shell Types Over 9 shell styles | Shell Types Over 19 shell styles |

| Shell Material | Shell Material Stainless steel | Shell Material Stainless steel or Brass | Shell Material Brass |

| Plating | Plating - | Plating Chrome on brass version | Plating Chrome |

| Cable Diameter | Cable Diameter 6.1 to 30.0 mm | Cable Diameter 1 to 23.5 mm | Cable Diameter 1.2 to 31.3 mm |

| NB of contact | NB of contact 2 to 64 | NB of contact 1 to 64 | NB of contact 1 |

| AWG | AWG 8 to 32 | AWG 8 to 32 | AWG 2 to 21 |

| Contact types | Contact types Multipole • Coax | Contact types Multipole • Coax • Fibre • Fluidic | Contact types High Voltage |

| Contact Termination | Contact Termination Solder / Crimp | Contact Termination Solder / Crimp / Print (PCB) | Contact Termination Solder |

| Test Voltage | Test Voltage up to 5 kV DC | Test Voltage up to 5 kV DC | Test Voltage up to 50 kV DC |

| Sealing Level | Sealing Level IP66 | Sealing Level IP68, 30 bars | Sealing Level IP50 |

| Temperature Range | Temperature Range -40°C to 160°C | Temperature Range -20°C to 200°C | Temperature Range -55°C to 230°C |

| Mating Cycles | Mating Cycles > 5000 | Mating Cycles > 1000 | Mating Cycles > 1000 |

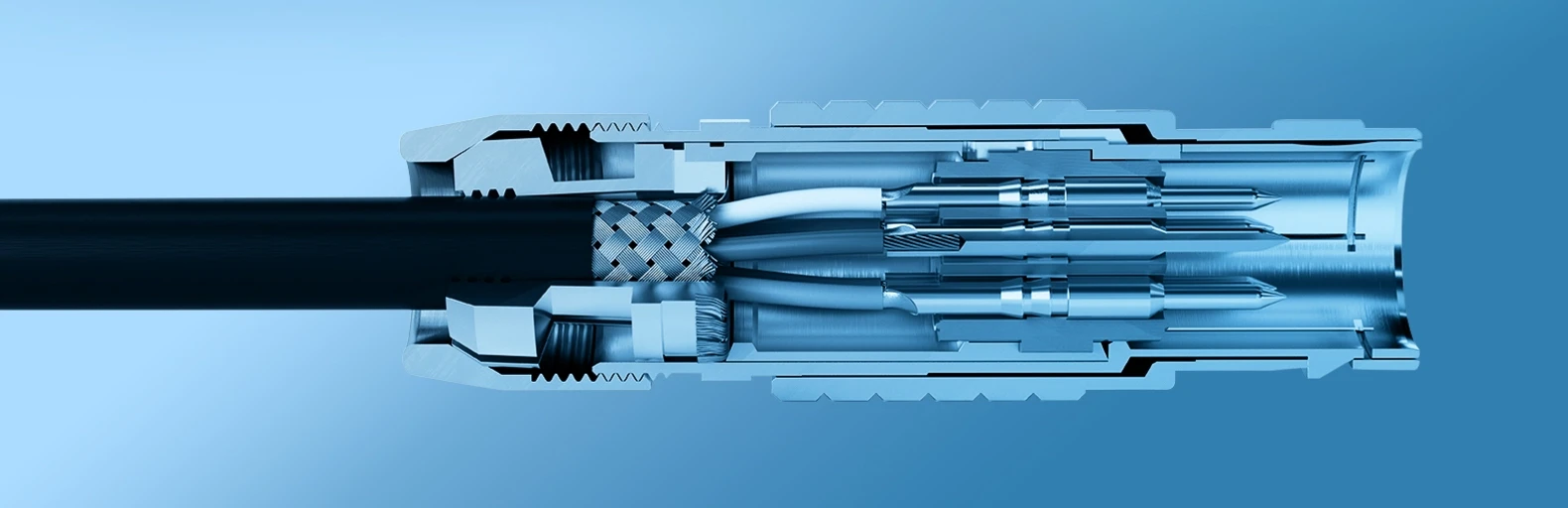

The N series offers remote handling self latching connectors suitable for operating in extreme environments. Fully compliant with nuclear quality standards, these stainless steel connectors are chemical and radiation resistant. The Push-Pull latching system with long alignment guides enables, rapid yet secure connections, high resistance to shocks and vibrations, and reliability even with frequent connection/disconnection. The range of options includes different sizes, elbow plugs, watertight and vacuumtight model, high-density low voltage, coaxial, triaxial, fibre optic, fluidic and thermocouple contacts as well as hybrid solutions are available.

- Plug

- Elbow

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 18 - 10

- Jacket cable outside diameter [mm]

- 12.60 - 13.50 mm

- Nb of contacts

- 3

- Termination

- Solder

- Wire Size/AWG

- 22 - 14

- Plug

- Straight

- Nb of contacts

- 8

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 7.60 - 8.00 mm

- Plug

- Straight

- Nb of contacts

- 10

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 7.60 - 8.00 mm

- Plug

- Straight

- Nb of contacts

- 10

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 8.60 - 9.00 mm

- Plug

- Straight

- Nb of contacts

- 26

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 8.60 - 9.00 mm

- Plug

- Straight

- Nb of contacts

- 22

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 10.10 - 11.00 mm

- Plug

- Straight

- Nb of contacts

- 20

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 10.10 - 11.00 mm

- Plug

- Straight

- Nb of contacts

- 10

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 9.60 - 10.00 mm

- Plug

- Straight

- Nb of contacts

- 4

- Termination

- Solder

- Jacket cable outside diameter [mm]

- 7.10 - 7.50 mm

- Plug

- Straight

- Nb of contacts

- 4

- Termination

- Solder

- Jacket cable outside diameter [mm]

- 9.60 - 10.00 mm

- Plug

- Straight

- Nb of contacts

- 7

- Termination

- Solder

- Wire Size/AWG

- 24 - 16

- Jacket cable outside diameter [mm]

- 8.60 - 9.00 mm

- Plug

- Straight

- Nb of contacts

- 7

- Termination

- Solder

- Wire Size/AWG

- 24 - 16

- Jacket cable outside diameter [mm]

- 6.10 - 6.50 mm

- Plug

- Straight

- Nb of contacts

- 2

- Termination

- Solder

- Wire Size/AWG

- 18 - 10

- Jacket cable outside diameter [mm]

- 10.10 - 11.00 mm

- Plug

- Straight

- Nb of contacts

- 30

- Termination

- Solder

- Jacket cable outside diameter [mm]

- 10.10 - 11.00 mm

Do you

have a

challenging

project?

No matter how harsh the environment may be, LEMO has a solution ready for you to implement today.

If not, we promise to relentlessly innovate and develop one for you.

Please take a moment to reach out and describe your project, technical specifications and deadlines. We are standing by and looking forward to hearing from you - and adding your business to our thousands of longstanding satisfied customers, partners and employees - very soon.