Locking Systems

The primary function of connectors is to maintain electrical continuity. Mechanical assistance with the coupling and uncoupling of connectors is known as locking. A secure locking system is essential for fastening the two parts in the operating position and ensuring an effective seal. The effective coupling of connectors is often referred to as mating.

Over time, various solutions for locking mechanisms have been devised, the most common being:

- Push-pull couplings

- Screw thread couplings

- Breakaway couplings

- Push and press release couplings

The choice of locking mechanism is dependent upon the connector's use and the environment it is subject to.

Technical Requirements

Uncompromised signals, data or power rely on dependable connections. Shocks, vibration, infiltration or simple mishandling can lead to disconnection. The result of which could be significant loss or damage to equipment, data or even life.

However necessary it may be, repeated connection and disconnection can pose challenges to connector design. A reliable locking system protects the contacts from wear and tear, extending the lifespan of the connector and reducing the costs of maintenance.

Ergonomic design is also critical. A connector which is easy to manipulate is quicker to use and reduces maintenance costs. A compact connector occupies less space and, in the case of LEMO's original Push-Pull connectors, requires no tools to disengage a secure connection.

These considerations are essential to the manufacture of resilient, high-performance connectors.

The Advantages of LEMO Solutions

Eliminate torque during the mating process for a rapid, robust yet easy connection. A coloured mark visually aligns the plug with the socket. Confirmation of mating is both audible and tangible.

LEMO Push-Pull connectors require finger clearance only on two sides of the connector since they are disconnected and withdrawn by a simple pulling motion. Reduced finger clearance creates greater density on a panel.

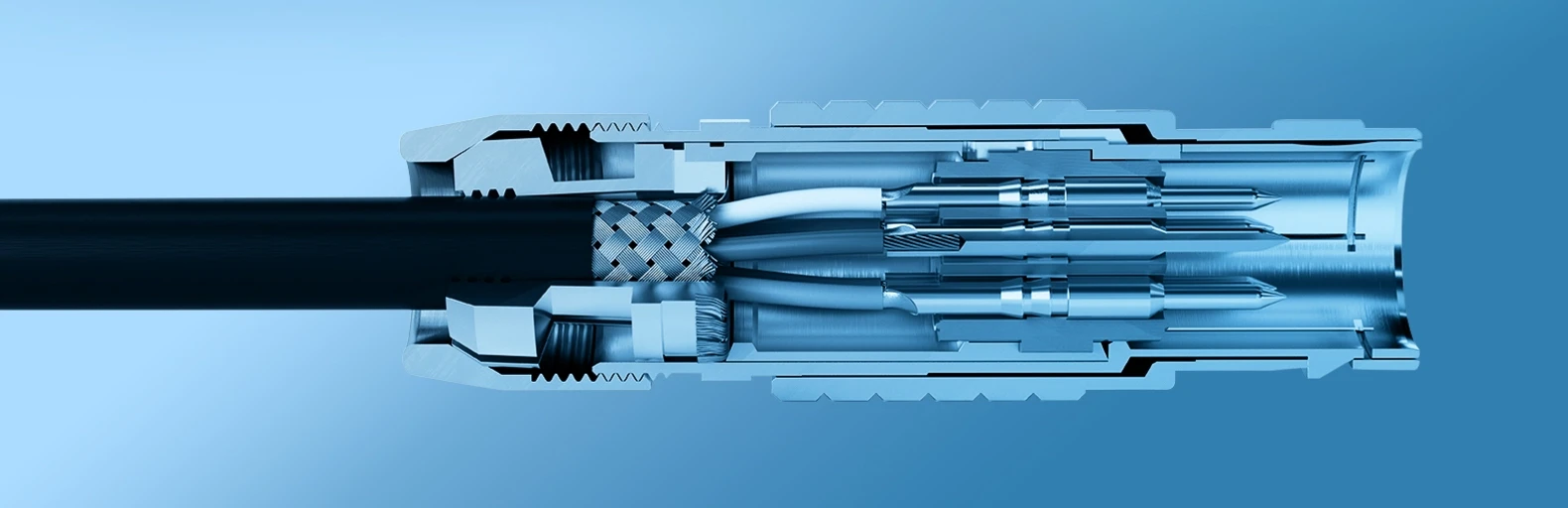

LEMO's female cylindrical contacts maintain a reliable electromechanical connection which usually outlives the equipment they are fitted to.

LEMO's innovative design recesses the lock with the shell, providing greater protection from ingress and wear and tear.

A collet provides cable strain relief, protecting cables from stress or damage.

Electromagnetic shielding provide screen efficiency superior to that of standard screened cables and most other connectors.

Alternative Locking Systems

LEMO's portfolio of connectors

come with a variety of locking mechanisms:

Do you

have a

challenging

project?

No matter how harsh the environment may be, LEMO has a solution ready for you to implement today.

If not, we promise to relentlessly innovate and develop one for you.

Please take a moment to reach out and describe your project, technical specifications and deadlines. We’re standing by and looking forward to hearing from you – and adding your business to our thousands of longstanding satisfied customers, partners and employees – very soon.