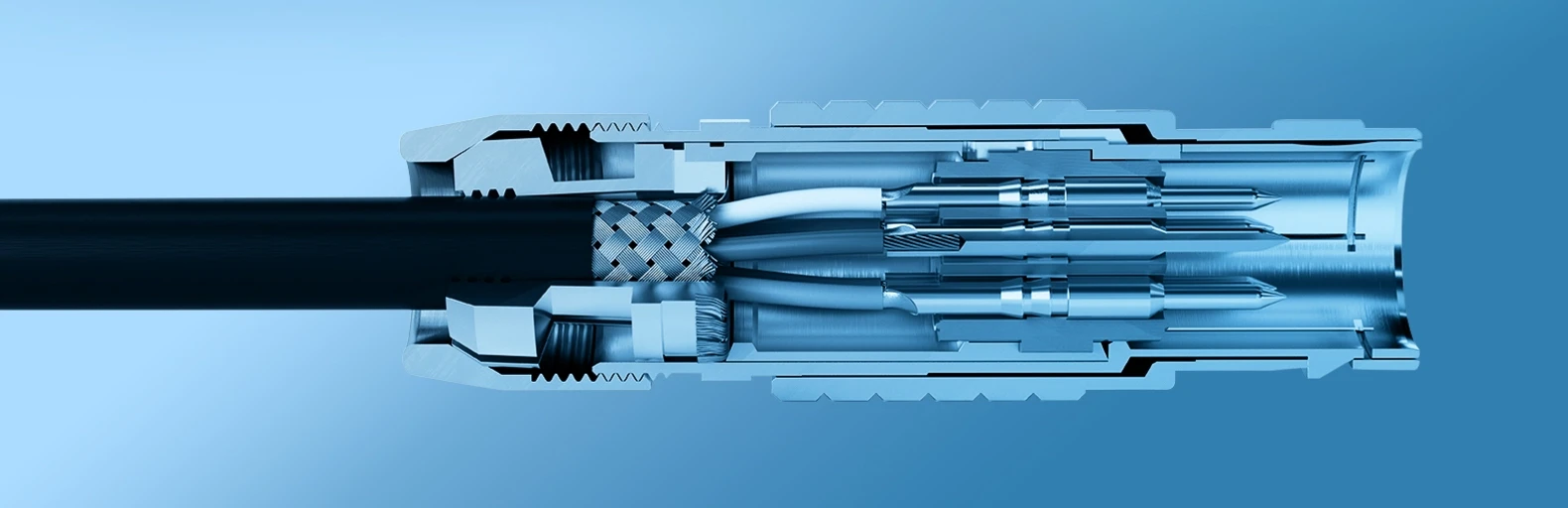

Fluidic Pneumatic Circular Connectors

Seamless Transmission of Fluids, Gases and Signals

Transmit liquids, gases, and electrical signals effortlessly with LEMO’s high-quality Push-Pull Fluidic Circular Connectors. Designed for precision, reliability, and ease of use, these connectors are ideal for industrial and medical applications where fast, secure connections are essential.

Benefits of LEMO’s Fluidic / Pneumatic Circular Connectors?

LEMO’s Fluidic / Pneumatic Circular Connectors are engineered for flexibility and performance. They come in two main models to meet diverse application requirements:

1. Single-Tube Model (Plastic Body)

• Specifically designed for air and inert gas transmission.

• Lightweight, cost-effective solution for simple gas-handling applications.

2. Composite Model with Shut-Off Valves

• Transmits liquids, gases, and electrical signals (or optical and coaxial) through a single connector.

• Equipped with shut-off valves, eliminating the need to block fluids or gases on the device side during disconnection.

• Compatible with waterproof and underwater designs for demanding environments.

Both models feature LEMO’s signature Push-Pull locking mechanism, allowing quick one-touch connections for faster setup and maintenance. This functionality reduces downtime and improves operational efficiency.

| Fluidic / Pneumatic contact | Fluidic / Pneumatic Connector REDEL P Series without shut-off valve |

|  |

Key Features of Fluidic / Pneumatic Connectors with Shut-Off Valves

Pressure Specifications

LEMO’s Fluidic / Pneumatic Circular Connectors come with different pressure handling capabilities based on the model:

- Single-Tube Model (A0 Contact):

o Max operating pressure: 2 bars.

- Small Shut-Off Valve Model (P1 Contact):

o Max operating pressure: 6 bars.

o Max airflow: 50 L/min.

o Max water flow: 0.80 L/min.

- Large Shut-Off Valve Model (P3 Contact):

o Max operating pressure: 6 bars.

o Max airflow: 210 L/min.

o Max water flow: 4.20 L/min.

Specifications Overview

| Series | Shell Materials | Contacts and Pressure Tolerance |

|---|---|---|

| B Series (Sizes: 2B–5B) | Chrome-plated brass, SUS303/304, PEEK, PSU, PPSU. |

|

| K Series (Sizes: 2K–5K) | Chrome-plated brass, SUS303/304. |

|

| N Series (Sizes: 2N–5N) | Chrome-plated brass, SUS303/304. |

|

| W Series (Sizes: 2W–5W | Chrome-plated brass, SUS303/304. |

|

| REDEL P Series (Size: 1P) | PSU, PEI. | o Single-tube model A0: Max operating pressure: 2 bars. |

Applications of Fluidic / Pneumatic Circular Connectors

LEMO’s connectors are trusted in various industries for their versatility and performance. Key applications include:

• Mixed control equipment combining electricity air and/or water.

• Devices requiring quick connections during installation.

• Medical devices, including surgical and dental equipment.

• Industrial machinery, where fluids, gas and signals need to be transmitted efficiently.

Compatible Connector Series

LEMO’s Fluidic / Pneumatic Circular Connectors are compatible with the following connector series:

Explore the full range of Fluidic Circular Connectors

Do you

have a

challenging

project?

No matter how harsh the environment may be, LEMO has a solution ready for you to implement today.

If not, we promise to relentlessly innovate and develop one for you.

Please take a moment to reach out and describe your project, technical specifications and deadlines. We’re standing by and looking forward to hearing from you – and adding your business to our thousands of longstanding satisfied customers, partners and employees – very soon.