VoidSense - Enhancing Reliability in Railway Track Monitoring

Maintaining railway tracks is essential for ensuring safe and efficient train operations.

A significant challenge in this area, particularly with tracks using ballast substrates, is a phenomenon known as "Voiding." Voiding occurs when ballast migrates away from critical areas beneath sleepers or crossings, resulting in voids that undermine track support. This can lead to excessive vertical movement of track components, causing cracks and eventual failure due to constant flexing under the weight of passing trains.

Traditional methods for measuring dynamic vertical deflection, such as the Dansometer and Voidmeter, have been in use since the 1930s. These manual devices require a track worker to physically measure deflections—a process that is not only labour-intensive but also exposes workers to hazardous environments. Furthermore, these devices are not well-suited to measuring deflections at complex track features such as crossings.

Development of VoidSense

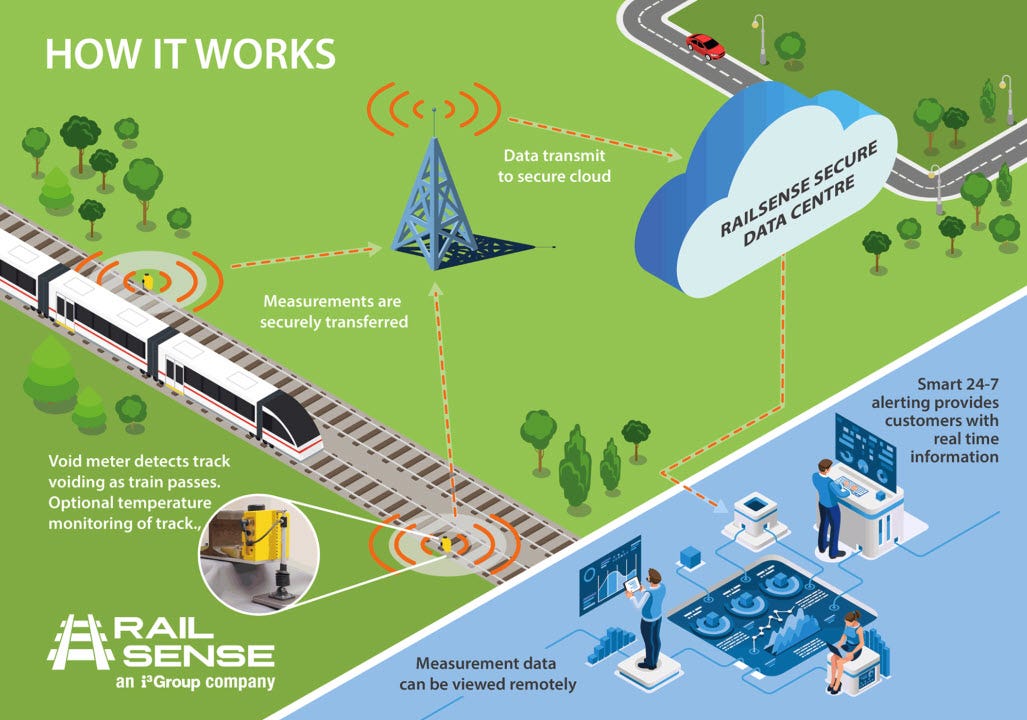

Recognising the limitations of manual Voidmeters, Network Rail developed a specification for a more advanced, battery-powered electronic device capable of providing remote data collection without manual intervention. RailSense responded to this challenge by developing VoidSense, a device that meets the specified requirements and has gained Network Rail approval. The VoidSense system is now being deployed across the UK and internationally, offering a flexible solution that can be easily installed, removed, and redeployed as needed. Crucially, VoidSense can be used on crossings, addressing a significant gap in the capabilities of traditional devices.

Connector Challenges

VoidSense uses a linear sensor which is clamped to the body of the device, and this connects to the device via a short length of screened cable and a connector, which was initially an M12-type industrial connector, but these were fiddly, difficult to confirm a positive connection and potentially open to manufacturing issues with screw terminal connections.

Nigel Dean, Senior Electronics Design Engineer BEng(hons), MIET, MPWI at RailSense, commented:

“LEMO very helpfully publish full specifications for their connectors, which many of their competitors do not. This made it easier for us to verify suitability for various applications. We now specify the LEMO M Series for our VoidSense sensor connector and have been delighted with the results. Our customers appreciate them as well and have commented on how secure the connection is.”

Benefits and Measurable Outcomes

The key benefit of the LEMO M Series connector is its exceptional reliability in the challenging conditions of railway track monitoring. This connector offers a rugged ratchet coupling, combining a lightweight, compact design with high vibration resistance and an IP68-rated screw-locking mechanism. This reliability is fundamental to the success of the VoidSense system, ensuring a stable connection between the sensor and the electronics unit.

Nigel Dean commented:

“A common remark we hear is, ‘LEMO connectors are so expensive.’ My response to that is simple: if you want the best, you have to pay for it. When you consider the cost of implementing an unscheduled line block on a major rail route due to product failure, you realise there’s no choice but to use the best components available, and there’s no doubt that LEMO fits into this category.”

Working with LEMO

Nigel Dean commented:

We contacted LEMO with our requirements, and their technical team suggested the M Series as a suitable replacement for our existing connector. Following successful trials, we are now fitting the LEMO connector to all our production builds. We have regular meetings with Scott McDonald, our LEMO sales contact, who has been very supportive, particularly when we needed to procure larger quantities.

RailSense’s experience with LEMO underscores the value of high-quality components in critical applications.

As VoidSense deployment expands, the collaboration with LEMO will continue to ensure the product’s reliability and ongoing success.