Navigating stormy waters

Created only 10 years ago, Norwegian Subsea develops high-performance cost-effective motion sensors that measure with accuracy the movements of a vessel or a marine structure. In real time and for the long-term.

In 1975, a young Steven Spielberg insisted on filming “Jaws” on the open sea, rather than in a Hollywood water tank. He wanted realism. Reality almost made his career sink: « It was a nightmare, going into the ocean was like working inside an earthquake. »

What Spielberg learnt at 26, maritime professionals have always known. This constantly moving, unpredictable environment makes any activity much harder. Luckily, there are technologies that bring a little order to the chaos. These include, motion reference units (MRU), sensors that measure the relative movement of underwater or floating vessels and structures.

Norwegian Subsea, a small cutting-edge company based in Oslo, is a benchmark for these specialised MRUs. It was created only 10 years ago, driven by its founder and CEO’s research in marine cybernetics.

“During my studies, I discovered how costly and bulky the instruments required for underwater navigation were”, says Fredrik Dukan. “We realised that we could combine our research in sensor fusion algorithms and microelectromechanical systems (MEMS) to develop MRUs that are both high-performance and much more affordable.”

Today, Fredrik Dukan is 39 years old, his company offers four MRU models and counts about a hundred customers, ranging from yacht owners to giants such as ABB and Saipem. With steadily growing sales, his small team (seven people at the time of the interview) needs to be reinforced. A fine success story.

The Norwegian company’s MRUs incorporate a high-quality MEMS three-axis gyroscope and accelerometer (and an optional magneto meter). They are capable of measuring–instantaneously and with centimetre accuracy–up to six degrees of freedom: “Pitch, roll, yaw and all the linear motion–heave, surge and sway. It also measures velocities and the associated accelerations.“

Obviously, they have also embedded the integrated circuits required for Norwegian Subsea’s advanced sensor fusion algorithms. These carefully refined algorithms fuse and weigh the data received from multiple sensors (those of the MRUs or others, such as pressure, GPS, Doppler, etc.) to obtain accurate and robust output measurements.

“Accurate in real sea motions”, adds Fredrik Dukan. “Not only in lab conditions!”

What are these merged data for? The CEO identifies three areas of application.

In “motion monitoring”, data are used to track what a vessel or a structure “lives through”, “in particular, to estimate its current safety or long-term wear and tear”. In “control”, data are used to activate a physical action to compensate for the movement. “For example, to stabilise a crane or a gangway so that safe landing can be ensured on an offshore station.” Finally, there is what Dukan calls “instrument compensation”: the MRU captures the movements of an instrument (wave radar, wind lidar, sonar, etc.) so that they can be “removed” from the measurements taken by the instrument. “Without this, it would be impossible to measure anything with accuracy–seabed or anything else–from a boat.”

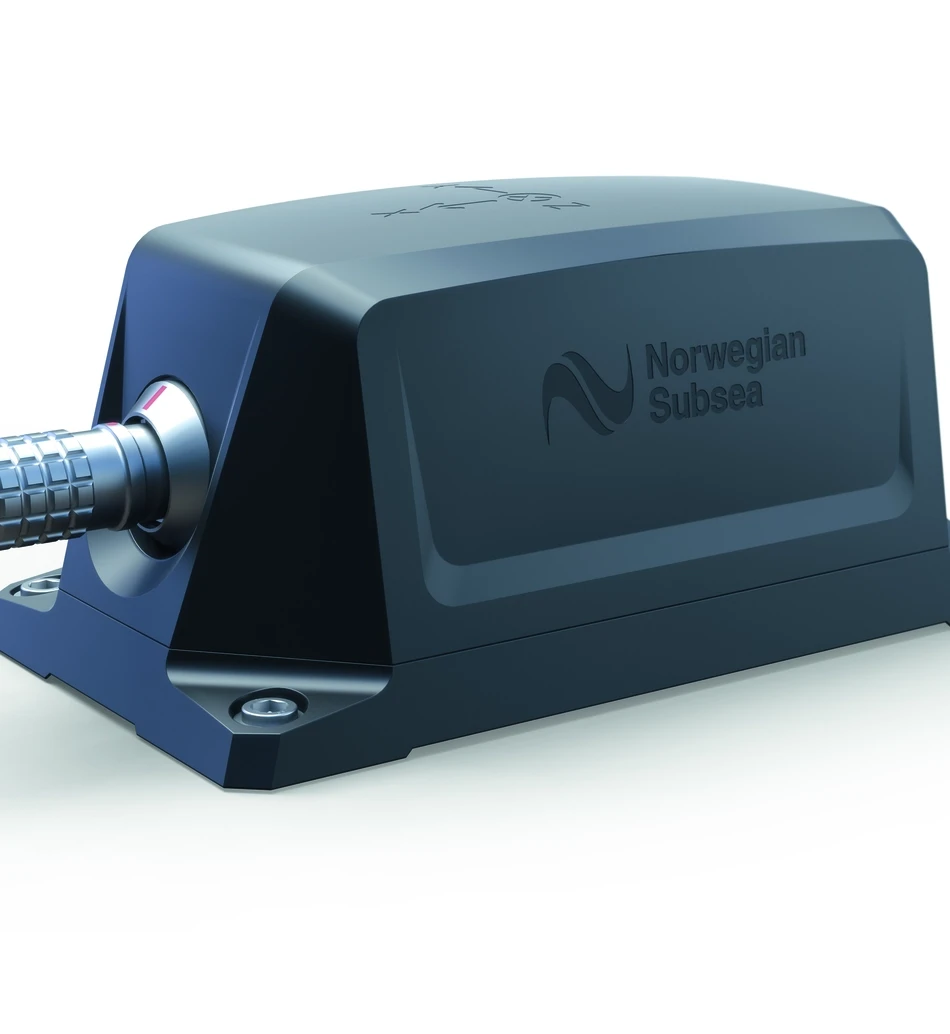

The Marine is the flagship product of Norwegian Subsea solutions. This MRU measures roll and pitch with an accuracy of +/- 0,05º à +/- 0,01º, as well as heave (to within 5cm or 5%). The Marine, protected by a robust anodised aluminium shell, is designed for the harshest weather conditions. It withstands temperatures from -40 to +80°C, and it can be used on a deck lashed by salt spray or submerged to a depth of 50m. Compact (less than 16cm by 9cm, weighing 1.2 kilos), it is easy to install anywhere.

Data can be exported via several port options (Ethernet, RS-232 and RS-485) and various industrial communication protocols. Its interconnection system: a LEMO Push-Pull IP68 K Series. The Swiss group also provides the assembly on a high-performance Northwire (a LEMO Group company) cable.

How about the Marine’s lifespan in such a harsh marine environment? “Outstanding,” promises Norwegian Subsea: it can operate perfectly for more than 100,000 hours in normal conditions (about 12 years). Moreover, unlike standard MRUs, “our MEMS sensors are so stable that they don’t need to be sent in for recalibration every 2-4 years!”

ShoreConnection is one of the many companies convinced by this MRU. In partnership with Norwegian Subsea, it has integrated the Marine into its Helideck Monitoring System (a helipad solution for oil platforms, super tankers and even luxury yachts). Fixed to the underside of the platform, the Marine can be used to check, at all times, whether or not landing conditions meet the safety standards laid down by civil aviation authorities. This is one of the “motion monitoring” applications.

Currently, Norwegian Subsea has another market in its sights: floating offshore wind turbines. “This industry is very interesting for us, since our MRUs can contribute at every stage,” explains Fredrik Dukan. “During the search for a site, they enable the buoys measuring the wind conditions to obtain accurate results. During construction, they contribute to stabilising the cranes. Once in use, they help to ensure that maintenance staff can safely disembark and embark. On the long term, to carry out structural integrity monitoring or to verify the pitch of the blades. Some of our customers were using equipment that cost several hundreds of thousands of francs”, adds the CEO. “Whereas they can now have something just as efficient, but much, much cheaper.”

The prodigious power of the sea should never be underestimated. By measuring and understanding its effects, Norwegian Subsea MRUs are helping to make this exacting environment a little less extreme for mankind or its latest inventions.