Fascinating today, revolutionary tomorrow

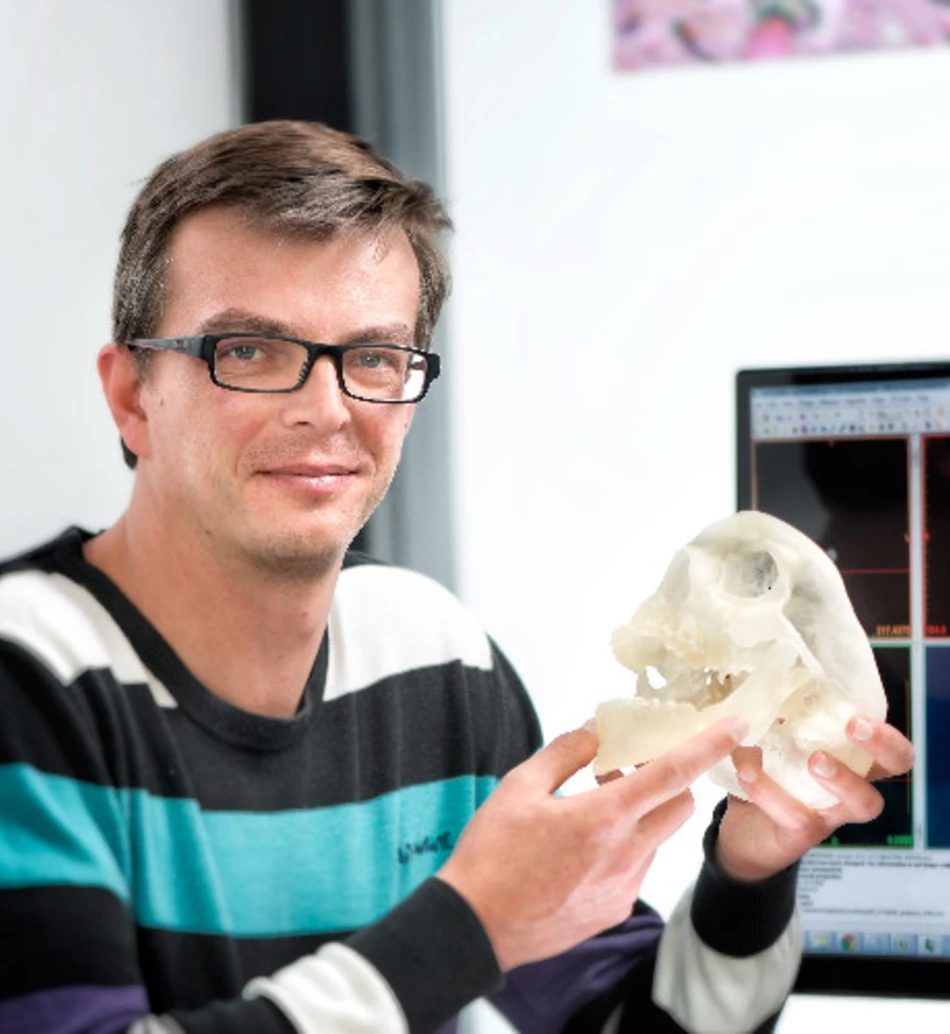

Interview with Sébastien Martinerie, 3D printing specialist at the CHUV in Lausanne, Switzerland.

At the Lausanne University Hospital (CHUV), as in many public hospitals in the world, 3D printing is still in the observation phase. But the current results are spectacular and the future outlook almost dizzying.

For how long has 3D printing been used in the medical field?

Sébastien Martinerie: For about ten years now… To begin with, it was used to create custom ear implants, dentures, etc. New applications, such as printing human tissue, are much more recent. This constant progress means that 3D printing is still an emerging technology in the medical field.

Can we already say that it is revolutionising medicine?

In my opinion, not yet. We were already produc- ing prosthetics and tissue before 3D printing. It has ‘just’ changed the way we do so, increasing precision and reducing costs and lead times. For me, 3D printing therefore seems less revolution- ary than things like scanners or MRI which have brought medicine into a new era. Of course, when we are able to print a functioning organ, that will be revolutionary.

Not a week goes by without the media report- ing a spectacular case of 3D printing in the medical world. Is the number of applications increasing?

Just five years ago, few people knew what 3D printing was, both in the medical world and elsewhere. Then it started to get popular and gain more media coverage. This had a snowball effect and many ideas and developments arose, including in the medical field. Several applica- tions seem futuristic, making them of interest to the media. Things like printing ‘springs’ which prevent respiratory channels that are too flex- ible from closing, titanium prosthetics to rebuild a patient’s smashed skull or an exoskeleton to help a young girl suffering from a muscle disor- der to be able to move again…

What are the advantages of 3D printing?

With 3D printing you can custom produce something highly complex for about the same cost as mass producing something simple! This is particularly valuable in the medical field, where each case – patient and trauma – is obvi- ously unique and the shapes are highly complex.

One of the key applications of 3D printing is its ability to help specialists better visualise things…

We print in 3D the area to be operated (organ, bone or even a tumour) and obtain a perfectly identical model of the original.

… a model far more telling than traditional 2D images or 3D modelling displayed on a screen? Absolutely! Surgeons can hold, manipulate and observe the printout as if they had the original in their hands. I can tell you about a recent ex- ample. It was only once a child’s heart had been printed in 3D that the American team realised the planned operation was not possible. They were therefore able to develop another solution.

Do surgeons use these models to prepare for their operations?

Yes, they can visualise the area to operate, de- marcate the area to be removed, check access pathways and the movements that will or will not be possible. They can also prepare, test and fully complete a prosthetic to be fitted. These stages are usually undertaken on the patient, during the operation. With the 3D models we print at CHUV, we have been able to reduce the duration of some maxillofacial surgeries by 50%. The prosthetic is ready before entering the operating block; the surgery is just for fitting it.

What about implant printing?

Implants are printed using biocompatible mate- rials, mainly titanium. We print hips, portions of jaw and skull and more... We can use a scan of the patient's intact bone - the opposite hip or other side of the jaw - and invert the image before printing. The result is an ultra-accurate implant, perfectly suited to the patient’s body. This makes the implants easier to fit than standard models. They also generate less wear in the recipient's body and promote osseointegration, therefore making it easier to heal and function again.

Even more recent, bioprinting is different. The print material is organic and we directly print living tissue…

With 3D printing, we can print tissue whose ge- ometry and structure are more complex than tissue grown in petri dishes. The tissue is there- fore much closer to reality and behaves more like real tissue. This opens up vast opportunities in pharmaceutical research, for example. Sub- stance tests are much more effective, we can eliminate much earlier those not appropriate, and use far less animal testing. The time taken to develop a drug can be drastically reduced; the financial impact is therefore huge. Signifi- cant indeed… Late April, Mercks concluded a research partnership for several years with Or- ganovo, an American company which produces human tissue using 3D printing.

Some even dream of printing organs, helping to save the lives of thousands of people cur- rently dependent on organ donation…

Talking of this today is tantamount to placing wild - and still unrealistic - hopes in the minds of those waiting for an organ. It is still impossible to print an organ, for the same reason that it is still impossible to print a smartphone: too many interlinked components and too many different materials… The most optimistic of people fore- cast organ printing possible ten years from now, but I am less optimistic. Once we do manage it, we’ll still need to conduct tests and handle the ethical issues…

… They are just prosthetics. We’re not creating life and no donor is implied, so what are the ethical issues?

Mainly relating to the separation between re- pairing a damaged body and improving a body...

… We could print 'improved' muscles for top athletes or titanium bones for super-soldiers... Unfortunately, like with any technological pro- gress, we cannot ignore what could happen to it in the wrong hands. 3D printing is not excluded. Look at the case of the young man who printed himself a firearm and then put the 3D file on the Internet for others to access.

When will 3D printing really enter daily practice at hospitals?

We are all convinced that 3D printing has a very bright future in the medical field. But the clini- cal, and especially financial benefits, have not yet been studied enough. Once these benefits have been measured, 3D printing will enter hos- pital routine. We’re not there yet, but the day is coming!