Black boxes for land forces

For decades, aircraft and helicopters have been thoroughly monitored to ensure flawless preventive maintenance. On the other hand, no similar solution has existed for military land vehicles, so ILIAS Solutions created one.

How many tanks, trucks or vans do I need to deploy for a military operation ? Which ones are in good condition ? How many spare parts do I need to embark to ensure their maintenance ?

These are questions Lars Dybdahl Nielsen used to go through while working for the material service of the Danish armed forces. Air forces get continuously surveyed data through rigorous monitoring processes, whereas he had to make decisions based on personal instinct and previous years’ numbers. So, the officer and engineer decided to create a device precisely recording the extreme life conditions of tanks, trucks, or military vans. He launched his startup Northern Vehicles Operations (NVO) in the northern suburbs of Copenhagen.

In 2011, the startup was acquired by ILIAS Solutions, a company proposing a fleet management software suite for air forces (NATO, Belgium and Chile are among their current customers). They were just about to enlarge their field of application and had no “ data logger ” for land vehicles. NVO’s solution was just what they were looking for.

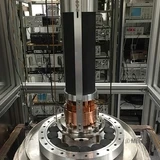

Today, after several years of preparation and cooperation with hardware / software integrator Prevas, the measurement device is ready. Simply named ILIAS I-HUMS (for “ intelligent health and usage monitoring system ”), the black box takes up barely more space than two packs of cigarettes one on top of the other. It is watertight, dustproof and resists paint and the type of shock that tank equipment is exposed to. Its connectors are also compact and robust : the LEMO 2T Series.

Inside the box, a GPS records the vehicle’s speed, whilst an inertial unit and gyroscopes measure triple axis acceleration. Thus, “ all the movements of the vehicle, bends, shock and jerks are recorded ”, explains Søren Theodorsen, Technology & development manager at I-HUMS. “ By connecting it to the on-board computer, it is possible to integrate internal factors as well (engine speed, oil temperature…). We then have a comprehensive recording of what the vehicle has actually endured. ”

The software ensures data protection. They are asynchronously encrypted before memory storage and transmitted upon return from deployment (up to 6 months later) by similarly encrypted messages. During the operations, the unit stays mute – no communication can be intercepted.

At the same time, ILIAS Solutions has been working for four years on transforming raw data into maintenance information. Multiplying measurements, using machine learning to improve its algorithms, and comparing results with external tests.

Once the vehicle is calibrated, the solution henceforth delivers a clear and detailed image of every vehicle’s condition, which is a big step forward compared to the engineer’s simple personal instinct.

It is possible to learn for instance about the general wear of the vehicle and schedule appropriate maintenance (neither too much, nor insufficient). Or else identify which vehicles are in the best condition ready for deployment. More specifically, it is possible to know when the brake pads need to be changed – not only based on mileage, but also on the brake force and frequency, possible overload and even the type of terrain covered (identified by algorithms). It is possible to control whether all-terrain vehicles are actually used elsewhere than on road. Or to determine precisely and separately when it is necessary to change the costly military oil.

“ All this contributes to increase availability and, first and foremost, to cut maintenance costs ”, concludes Theodorsen. “ You need fewer vehicles to do the same job. ” Fewer vehicles, so less transport, spare parts on site, less equipment, staff, administration… : “ the entire logistic footprint is reduced. ”

The benefits are not only logistic or financial, points out the specialist. A vehicle that breaks down can cost the operation’s success, even human lives

So, I-HUMS has major sales arguments, but its success needs yet to be ensured. “ Everything goes rather slowly on the defence market, where it’s all about public money and political decisions ”. They also need to convince land forces to adopt a process that they have not requested so far. These last years, ILIAS Solutions has increased the number of demonstrations and loans of I-HUMS. “ We keep training and informing, so that potential customers can measure the actual interest of these data ”.

Not only armies are canvassed, but OEMs as well. The very first customer is by the way Nexter, the French military vehicle manufacturer. OEMs do not measure wear and tear to schedule maintenance “ but to improve vehicles under development ”, which can help to meet the ever-increasing requirements of defence, as well as offer protection in case of defective claims by the clients.

ILIAS Solutions banks cautiously on annual sales of several thousand I-HUMS. With armies using hundreds, or even thousands of vehicles, the figures could rapidly increase.