Intelligent ventilators

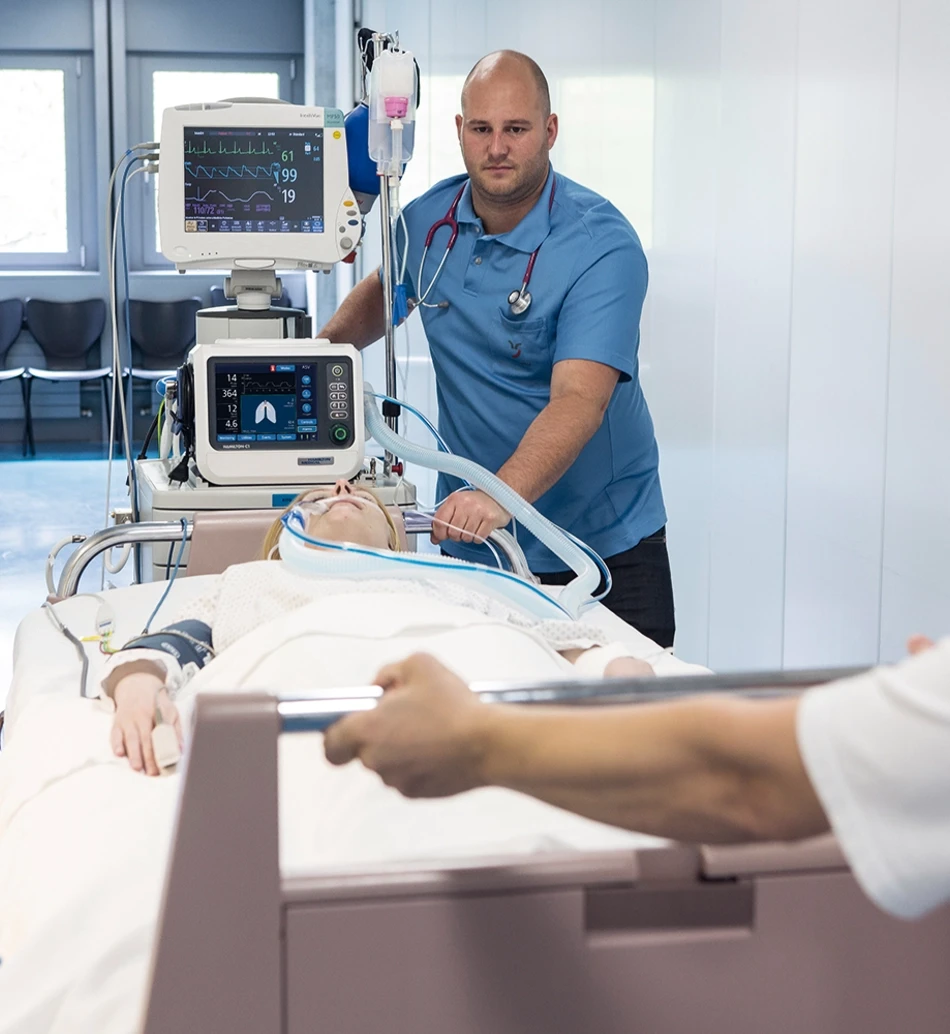

Hamilton Medical’s respiratory assistance equipment optimises ventilation and saves time for medical staff.

Two qualities of critical importance for intensive care units overloaded by the COVID-19 pandemic.

There is only one available ventilator. Which patient should it be given to, knowing that the others will die ?

This is the worst-case scenario which was experienced much too often in Italy during their peak infection period earlier this year and that all countries have been trying to avoid at all costs. The demand for ventilators has skyrocketed. France aims at tripling, the USA at quadrupling its fleet. Manufacturers have boosted their efforts to meet the demands. Among them, Hamilton, a leader with 20% of the market for ventilators used in intensive care units.

Since early 2020, the Swiss company began to work in 2 shifts, seven days a week. By the end of April, they have already tripled their usual annual production, delivering thousands of machines worldwide and continuing to increase the pace.

As the pandemic continued to spread, it was discovered that the SARS-CoV-2 (COVID-19) attacks almost all body organs, with the lungs being its primary victim. In the most severe cases, the virus can completely stop their dual function – providing oxygen and withdrawing carbon dioxide from the bloodstream. When this happens, the patient needs to be intubated.

Such intervention is never simple or harmless, points out Kathrin Elsner from Hamilton Medical.

“ Mechanical ventilation is a very unnatural process for the lungs. Inappropriately applied, it can do a lot of sometimes irreversible damage to the lung tissue. Damaged alveoli will not recover. And if too many alveoli are damaged, consequences can be fatal. ”

During intubation (1 or 2 weeks, if all goes well), the patient’s condition and needs vary all the time. With traditional ventilation systems, the settings need to be constantly monitored and fine-tuned. This requires time and personnel, two resources limited in intensive care, especially in the middle of a pandemic. Hamilton Medical has a solution to address this issue.

The company was created in 1983 with a clear vision : to produce automated ventilation modes and intelligent systems that can instantly adapt to the patient’s needs. On the one hand, it could improve care. On the other hand, it could save time for medical staff, who could then do other important jobs.

Hamilton took a first decisive step in 1998 : they launched the first “ intelligent ventilation mode ” (filed under the trademark ASV standing for “ adaptive support ventilation ”).

“ ASV simplifies ventilator settings down to three parameters the clinician has to adjust ”, explains Kathrin Elsner. “ Minute volume (the volume of gas per minute), PEEP (the pressure in the lungs above atmospheric pressure) and FiO2 (the percentage of oxygen in the gas mixture). ” ASV has been adopted by many hospitals around the world, becoming a standard for artificial ventilation.

In 2010, a further major step with the INTELLiVENT-ASV that Hamilton Medical presented as the world’s first ventilation autopilot. Hi-Tech and algorithms “ make the ASV settings fully automated using two additional sensors. ” The first sensor (equipped with LEMO’s REDEL P connectors) measures carbon dioxide, the second oxygen saturation. In short : INTELLiVENT-ASV can do everything on its own, “ constantly adapting to the patients’ condition and needs and keeping them within lung-protective parameters.”

INTELLiVENT-ASV includes a feature helping to wean the patient, as soon as possible, off the ventilator. “ Quick Wean assesses the readiness to wean criteria for the patient, as set by the clinician. It can perform so-called “ spontaneous breathing trials ” where the patient is encouraged to breathe spontaneously and without support. If those trials are successful, the clinician can consider extubating the patient. ”

Hamilton Medical proposes ten models of mechanical ventilators (with a whole range of accessories and consumables). They meet various needs of many users. “ Our ventilators can ventilate all kinds of patients from neonates to adults, active or passive, either intubated or via mask or nasal prongs. They all offer traditional and state-of-the-art ventilation modes and therapies.”

The flagship products are the HAMILTON-G5/S1 and the HAMILTON-C6. The highly compact HAMILTON-T1 (equipped with LEMO B connectors) has become a reference in patient transport.

The HAMILTON-C1 and HAMILTON-T1 models are the most demanded in the current crises. “ With their integrated turbine, they are independent of compressed air. They are easy to use and, despite their small size, offer all the features of a full-sized ICU ventilator. All this makes them very well suited for pandemics.”

Hamilton Medical employs a staff of 400 in Bonaduz, a village nestled in south-east Switzerland. Plus 100 more around the world. The company attributes its success to its innovations and the ease of use of its solutions. “ But a big part of it is that we live for ventilation technology, the whole company revolves around it ”, concludes Kathrin Elsner. “ This focus makes us unique among the other big players on the market. ”