The birthplace of future technology

LEMO opened its Japanese subsidiary exactly 20 years ago. LEMO Japan has distinguished itself as a think tank, developing innovations that would become world references. A forerunner in fields as varied as HD television and the nuclear industry, the subsidiary is currently working on a new device wich could potentially prevent a large number of road accidents.

Japan: a highly demanding market for technological innovation, with a strong growth potential and serving as the gateway to Asia. These three major assets led LEMO to open its subsidiary in 1994, after having been represented by a distributor for many years. Shortly afterwards the small team, which has now grown to a staff of 39, was contacted by the Japanese Television ARIB committee which was seeking to determine new standards for connectors and cables as part of their objective of switching Japan over to digital TV production and transmission completely.

This new technology was developing rapidly, particularly at Sony - who were already developing smaller and yet higher definition cameras. LEMO was invited to present proposals for a new connector to the committee, and after a series of demanding tests on the concept, along with requested modifications, the LEMO product was chosen as the basis for the new standard.

A total of 6 connector manufacturers had presented their options, but the LEMO connector was the only one that passed all the necessary tests. In 1998 the company launched, in cooperation with the Swiss and UK LEMO R&D teams, its 3K.93C connector which has since become the global standard in HD television and successfully installed in many prominent venues around the world.

The arrival of Akira Umemura at the head of LEMO Japan in 2001 marked the start of a new era. Until then mainly dedicated to import and sales, the subsidiary developed cable assembly through several Japanese subcontractors, whilst maintaining complete control of the management and quality processes. This control was further enhanced by creating a large local stock which increased responsiveness. Today cable assembly represents almost half of the company's business.

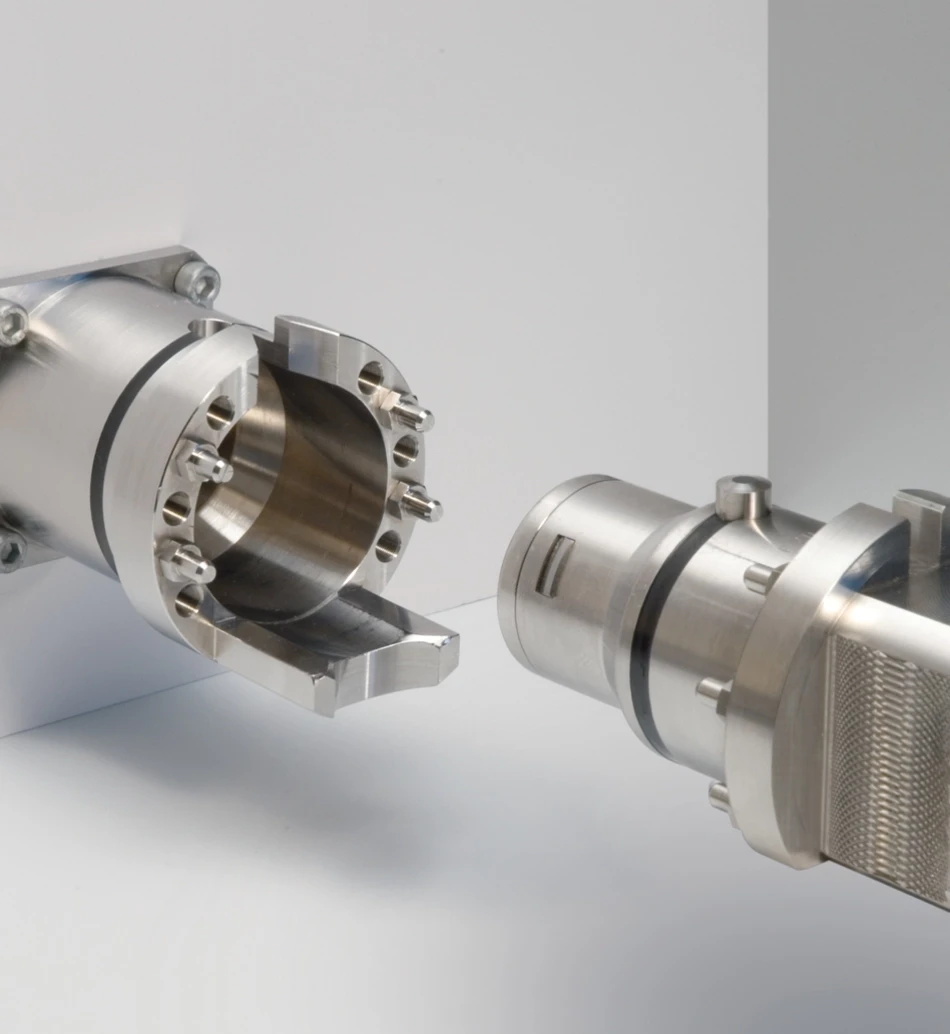

2001 also saw the launch of another major project regarding N series connectors. Developed with the Japanese national centre for nuclear waste recycling, these remote controlled connectors are now used worldwide.

LEMO Japan was developing fast and opened an office in Kobe in 2003. The company moved to a new 1000 m2 building in the Mita area, the best in Tokyo, in 2012 with a grand opening ceremony to celebrate its 18 years of success in Japan.

The activities of the subsidiary now include sales, administration, logistics and a technical department, as well as a mechanics workshop for prototype production.

Among its current projects, LEMO Japan is cooperating with several other companies on the development of a new application, involving both medical and automobile technology. Cardiovascular diseases are the second highest cause of mortality in Japan and road accidents due to medical incidents while driving are frequent. This device will detect warning signs from the driver through various measurements - cardiogram, blinking of the eyelids, blood oxygen, etc. and will provoke a call to emergency services with geolocalisation and vehicle immobilisation.

In the long term, for all types of applications, the company aims at extending its product range to complete connection solutions, including connectors, cables, enclosures and active components.