Sculpteo: the success of a factory in the cloud

There began to be a lot of talk about 3D software, 3D objects and 3D printing in 2009” explains Clément Moreau, co-founder of Sculpteo.

“For us, it was a new revolution in the history of industry. So we started to get ready for when the big wave would arrive…”

Clément Moreau created Sculpteo in Paris, France with Eric Careel (also founder of With- ings connected objects) and Jacques Lewiner. The concept – as Moreau likes to summarise it – is a “factory in the cloud”. You upload a 3D file to the website, Sculpteo prints it and you re- ceive the object in the post. There were already a few competitors (Shapeways was launched in the United States in 2008), but the concept was still very new.

The anticipated wave arrived and Sculpteo was not one to miss out.

Mid-July 2015 and the French company an- nounces it has been chosen by the giant HP to be an exclusive partner. Sculpteo will produce what emerges from the “Sprout”, HP’s brand new generation of PCs for 3D creators.

“Such an amazing acknowledgement,” rejoices Clément Moreau. More like a confirmation. HP joins other leading names who have already entrusted their 3D printing to Sculpteo: eBay, Amazon, Orange, the French postal service and supermarket giant Auchan (who has just invested in the company).

Back in February 2010, Sculpteo had begun by targeting consumers. This helped the com- pany build its image and test the market. But as expected, the market was not ready (crea- tion and use of 3D files is still not mainstream). So the start-up reacted fast by opening up to professionals and by developing what was to become its trademark: software tools that con- siderably simplify the work of its users.

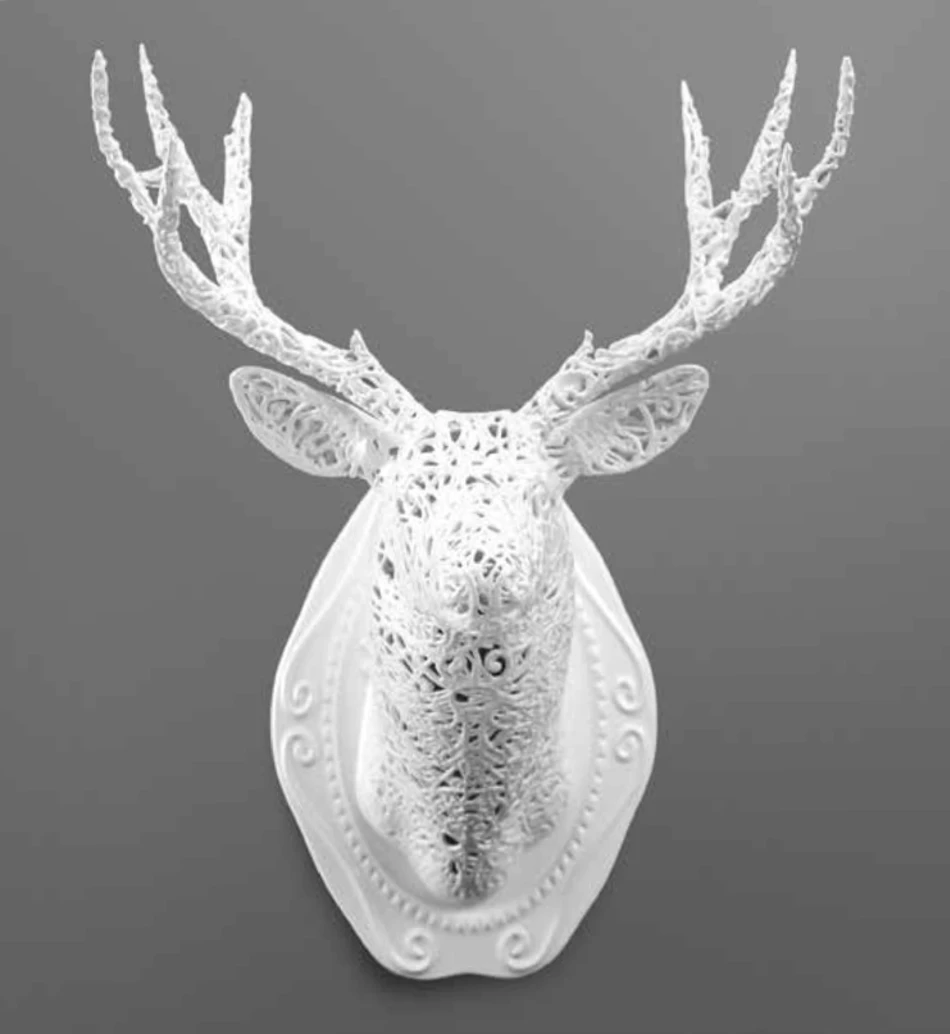

Today, these tools enable precise online control of each production stage. The uploaded 3D file can be checked. Cavities can be incorporated to reduce the quantity of materials used (and therefore the cost). A final rendering can be obtained to check – or change – the choice of materials, finish and colours (48 possible combinations). The user can also optimise the layout of objects in trays to reduce the quantity of materials used and printing time.

These control and improvement tools have also hit the mark with professionals. They even allow them to print end products, not just pro- totypes. For example, the American company AudioQuest prints the grilles for its new Night- Hawk headphones at Sculpteo.

Accessories for smartphones and tablets, small figurines, jewellery, unit production or medium production runs… Sculpteo can print everything, or almost. The object must meas- ure less than 30 cm3, cannot be a weapon and the customer must demonstrate ownership of copyright.

The potential is there. Sculpteo’s turnover doubles each year and demand is constantly increasing.

The company does not fear the success of per- sonal 3D printers either.

“On the contrary,” asserts Clément Moreau. “The more 3D printing enters the mainstream – as is already the case in the US where dedi- cated software is becoming as natural an item as an office suite – the more the demand for professional quality services increases”.