Excellence in Manufacturing and Supply

A history of industrial expertise

For over 75 years, LEMO has integrated its in-house expertise to develop an ecosystem where excellence in design drives quality manufacturing, and where local expertise and a global supply chain make for superlative customer support.

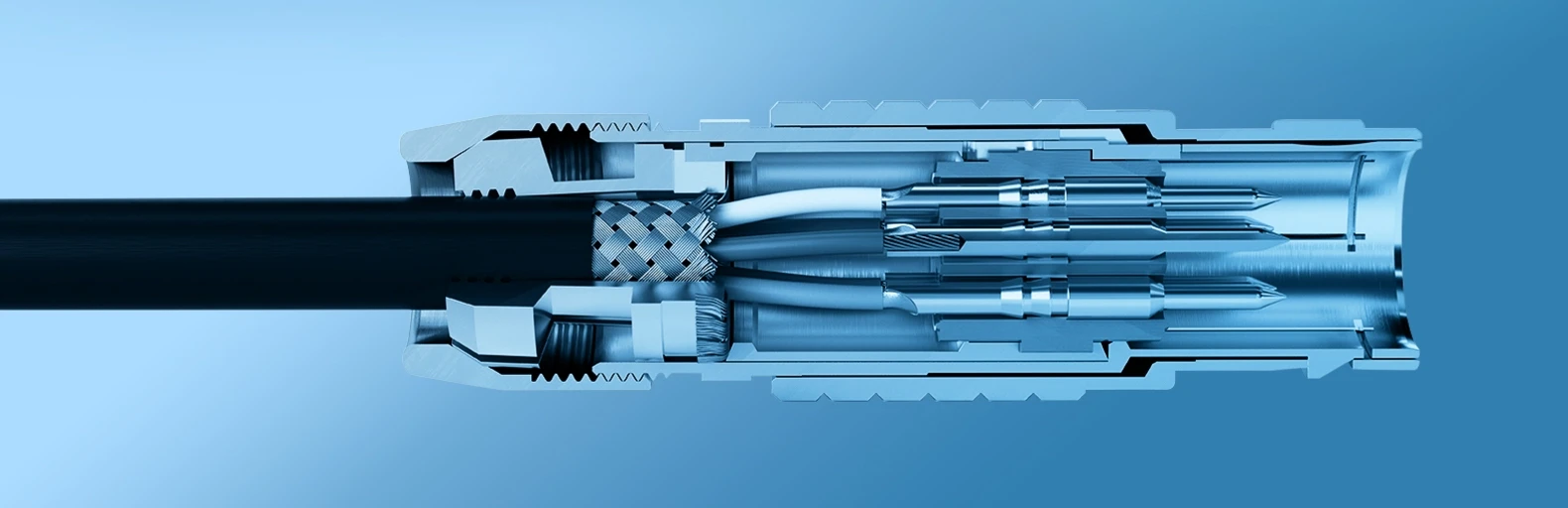

Continuous investment, training and development are the foundation on which our teams, tools and products are built. Often led by the uncompromising demands placed on our cables and connectors, LEMO ensures its designers, technicians and operators are equipped with the state-of-the-art technology they need to provide high-performance connectivity. Regularly custom built, LEMO machinery is designed to ensure the reliability, durability and quality of our products against customer specifications.

It would be near impossible for us to control the perfect quality of our solutions without fully controlling our entire production chain. Therefore, we have continuously integrated new competencies into our manufacturing capability to reduce our dependence on external suppliers and have become an almost fully vertically integrated, independent company (95%+).

From raw material procurement, tool making, machining to injection moulding, surface treatment, (which also has its dedicated research laboratory), manual and automated assembly, as well as cable assembly, plus all the testing: all the processes are entirely supported by in-house capabilities. We also develop and produce our high-performance cables and wires.

Vertical integration at the service of your solutions

The LEMO Group has always been able to maintain full control over its business, with the aim of ensuring consistently high quality and performance of its solutions. Such independence is what ultimately enables LEMO to successfully re-invest in operations, people and research and development for continuous improvement.

Maintaining Leadership

LEMO is acknowledged as a market leader because in our quest for excellence and quality we built up a fully controlled supply chain. From concept to delivery, 95% of our added value is generated in-house.

Highest quality standards

At LEMO, manufacturing processes are kept in-house to ensure that our rigorous standards are met. Machining, injection moulding, surface treatment, potting, over moulding… Our skilled technicians and automated assembly lines guarantee our strict adherence to excellence.

Continuous improvement and efficiency

Throughout its over 75 years' history, LEMO's owners have always massively reinvested their profits in cutting edge technology, equipment and continuous improvement. Combined with sustainable growth, a long-term vision and creativity, this is how we have managed to maintain our market leader position.

Business Continuity

Maintaining control of the supply chain is fundamental to LEMO's ability to ensure the highest quality. Deploying our manufacturing skills across five production sites assures business continuity and a secure supply for customers.

Do you

have a

challenging

project?

No matter how harsh the environment may be, LEMO has a solution ready for you to implement today.

If not, we promise to relentlessly innovate and develop one for you.

Please take a moment to reach out and describe your project, technical specifications and deadlines. We are standing by and looking forward to hearing from you – and adding your business to our thousands of longstanding satisfied customers, partners and employees – very soon.